The goal was to create a dynamic, exciting, and unusual stadium for FC Felcsút

System Novum Innovatív Kft.

The new home stadium for FC Felcsút in Hungary features a complex and unusual concrete and timber roof, which required both engineering ingenuity and flexible formwork solutions to build.

The Goal

To create a dynamic, exciting, and unusual stadium for FC Felcsút

The new home stadium for Felcsút’s local football team is a dynamic combination of concrete and wood – unusually, the slanted grandstand roof is supported by striking timber arches that fly over the seating areas.

The Project

Summary:

The new stadium will provide seating for 3,500 spectators under the grandstand roof. Together, the contractor and MEVA designed a cantilevered shoring system that would allow the roof supports to be cast without damaging the playing field. The slabs for the stadium’s lower levels were also poured with a limited amount of slab formwork to save materials and storage space on site.

Challenge:

Casting the grandstand roof was a particular engineering challenge as the installation of the playing field had already begun and any shoring structures would damage it. In addition, there was a limited amount of storage available on site, so minimising the formwork materials was a necessity.

The Solution

1. Flexible formwork solutions

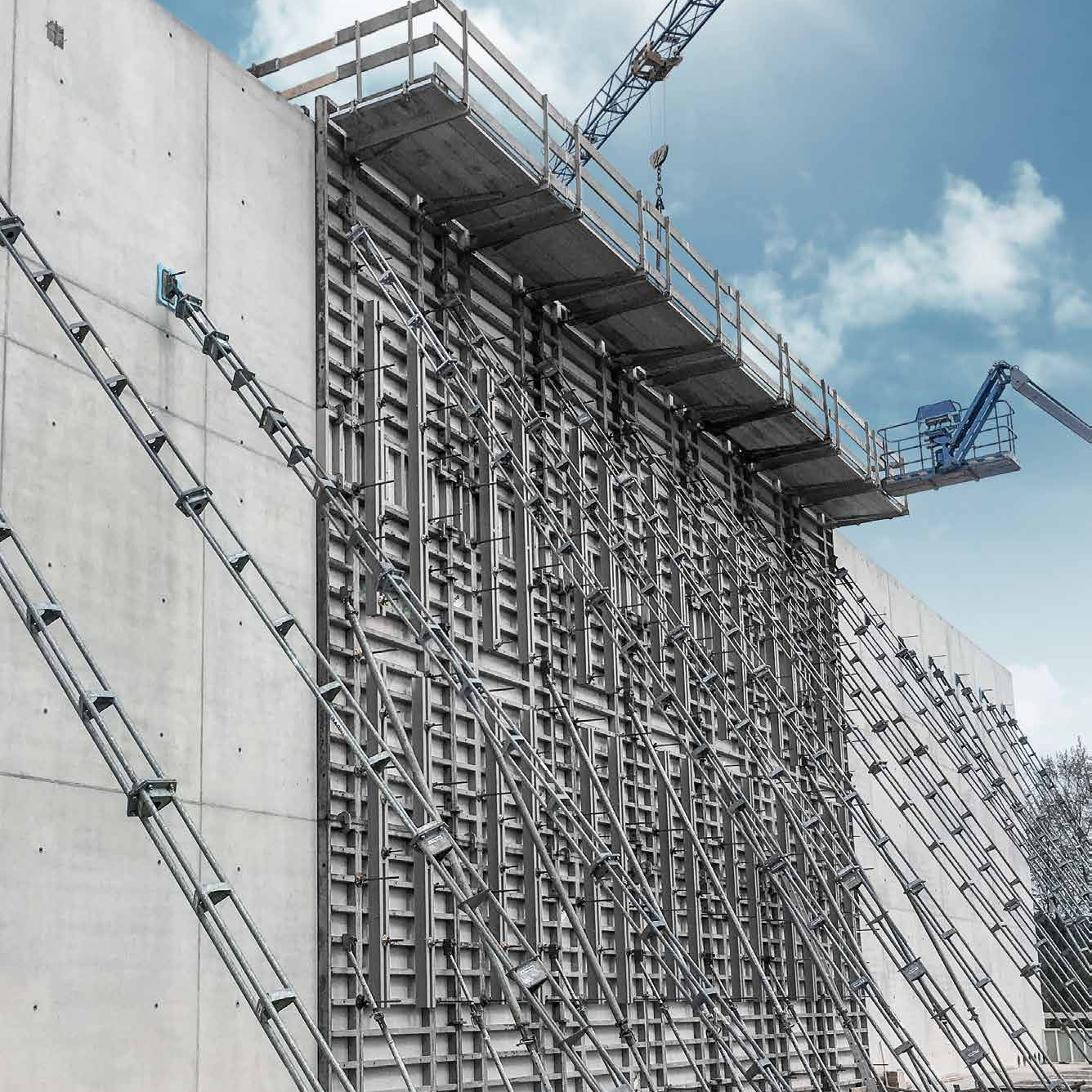

With 28,000 m² of walls to pour – some up to 3.7 m high – and 17,000 m² of slabs to cast, as well as columns and roof slabs, a wide range of flexible formwork solutions were required to deliver the architects’ vision.

With a two-year construction programme to deliver, the contractor chose to take advantage of MEVA’s RentalPlus scheme, which would cover all repairs and reduce time, effort, and administrative costs.

The formwork solutions chosen included the heavy-duty Mammut wall formwork, which was combined with StarTec wall panels and the STB 450 support frame.

The StarTec panels were ganged to finish 20 to 30 m long wall slabs in single pours, supporting the tight time schedule. Where fair-faced concrete was required, MEVA WTS 20 with alkus all-plastic facing was used. In addition, the MevaDec and MevaFlex slab systems, CaroFalt column formwork, MEP HD shoring towers, and R630 push-pull props were also chosen.

2. Optimised slab formwork design

To save time and space, the slabs for the stadium’s lower levels were meticulously planned in order to optimise the materials needed. The MevaDec slab system was chosen for its ability to be stripped early, as well as its quick and easy removal process.

By organising the pours into cycles of 600 m², the panels could be stripped just three days after the pour and re-used elsewhere. This meant that the 17,000 m² of slabs could be cast with an inventory of just 1,200 m² of the MevaDec slab system.

3. Innovative engineering approaches

a) Strong shoring solutions to handle high wind loads

While being built, the wooden roof of the grandstand needed to be temporarily supported. However, the height of the supports meant that there would be high wind loads – the supports would need to be 20 m high on the eastern side of the grandstand and 24 m high on the western side.

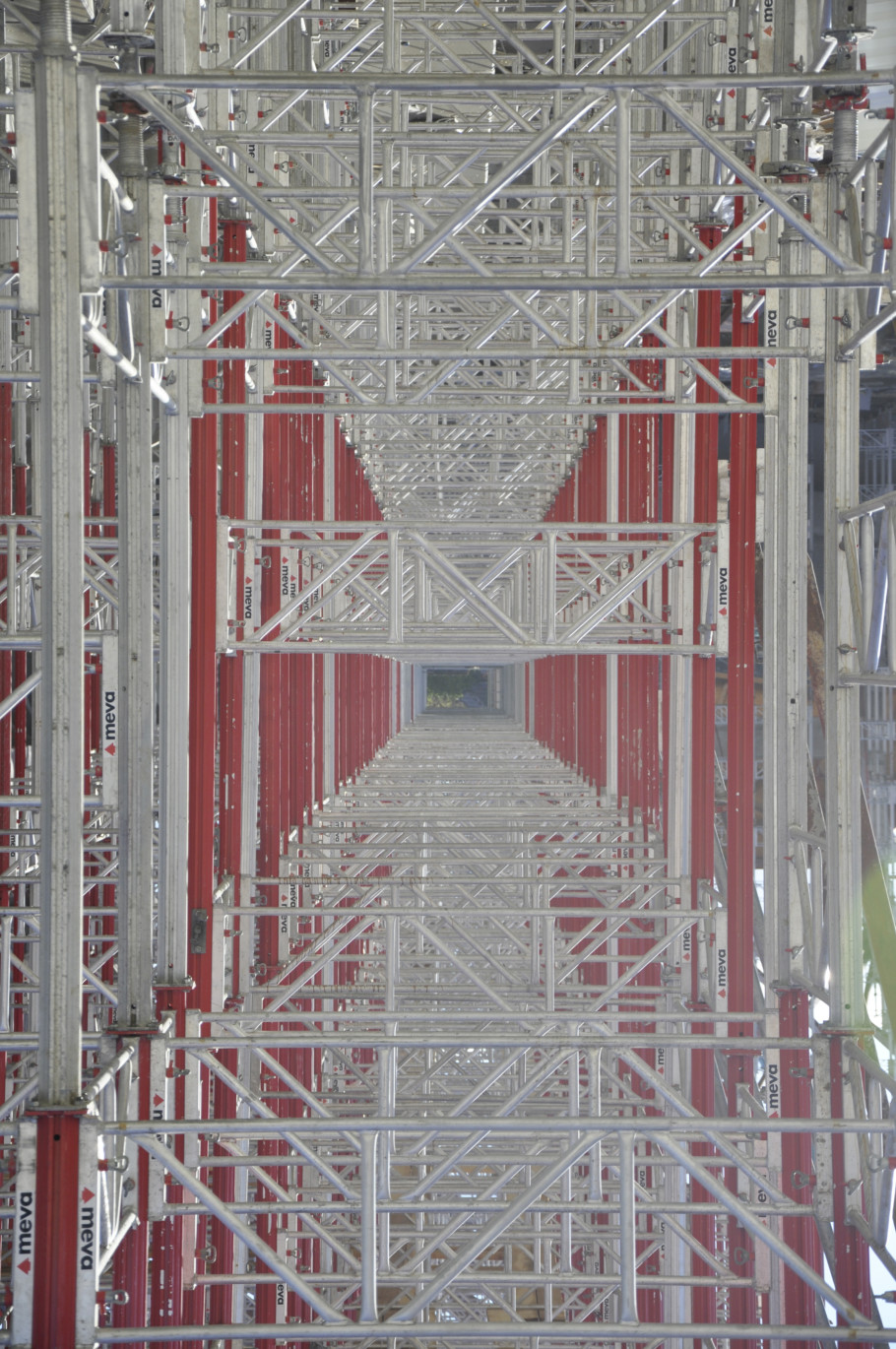

This was achieved with MEP shoring towers, which proved to be ideal as free-standing supports thanks to their rigid frames.

The supports were anchored to the concrete structures using R630 push-pull props and tension belts. Thus secured, they were able to withstand both the wind load and the load of the roof.

b) Innovative engineering solutions to allow concurrent construction activities

The western part of the stadium’s grandstand was a particular challenge. The MEP shoring towers could not rest on the ground because the planting of the playing field lawn had already begun, and the towers would have damaged the field as well as delaying this section of the works.

To overcome this, the engineers placed MEP shoring towers (reaching 2.2 m over the field) higher up and fixed them to the towers already in place under the grandstand. The additional loads were dealt with by using push-pull props and column connectors.

4. Specialist formwork for architectural applications

a) Freeform roof columns

The unusually shaped columns which supported the timber roof required special steel formwork to create the freeform shapes. Where possible, any standard 60 by 60 cm columns were formed using the CaroFalt column formwork system.

b) Fair-faced architectural concrete

The walls of the ground floor were left exposed as poured and required a high-quality, architectural finish. To achieve this, the contractor used the MEVA WTS 20 beam and facing wall system, which comes with the smooth alkus all-plastic facing to achieve the desired finish.

c) Slanted floor slabs

The ground floor and grandstand had slanted floors, which required a different solution to the other slabs in the project. The contractor decided on the conventional beam method using the MevaFlex and a facing made of plywood sheets for the flexibility that it offered, enabling the precise floor angle to be achieved during the pour.

The Outcome

The project was delivered in just two years, despite the complexity of the architecture and the size of the works. The project has since been described as one of the world’s most beautiful stadiums, thanks to the seamless interplay between the concrete structure and unique timber roof.

Featured Products:

- Wall formwork Mammut

- Wall formwork StarTec

- Slab formwork MevaDec

- Slab formwork MevaFlex

- Column formwork CaroFalt

- Support frame STB 450

- Shoring system MEP

- R630 push-pull props.

Client & Construction Co: System Novum Innovatív Kft.

Project: Sports Stadium

Location: Felcsút, near Budapest, Hungary

Developer: A Felcsúti Utánpótlás Neveléséért Alapítvány

Engineering & Support: MEVA Zsalurendszerek Zrt., Budapest, Hungary.