Architectural concrete masterpiece

The cuboid-shaped extension of Zurich Art Museum is a shining example of the potential of fair-faced concrete, despite the architectural and structural engineering challenges.

The Goal

To create a light-filled concrete sculpture with a high-quality finish

Based on a design by star architect David Chipperfield, the new extension to the Zurich Art Museum was designed to be an open, light-flooded, cuboid-shaped building. To achieve this vision required a demanding specification, such as sharp edges on all corners, high-quality architectural finishes, and a uniform joint pattern on the wall and floor slabs.

The Project

Summary:

The extraordinarily detailed design placed great demands on both MEVA and the contractor, who were able to deliver an architectural masterpiece.

Challenge:

The complex geometry and high level of detail specified on this project created architectural and structural engineering challenges, which required innovation and care to overcome.

The Solution

1. Attention to detail

a) Creating a uniform joint pattern with Mammut 350

An important aspect of the planning and implementation of the entire building was the requirement that all corners be sharp-edged. In addition, the joint pattern was specified by the architect throughout the entire building. These requirements were a significant challenge in the large hall.

Despite openings and flights of stairs in various locations, the joint pattern had to extend precisely and without offsets over the entire height, and even on the large concrete beams. The work therefore required exact planning and had to be performed with great care during construction.

For this reason, the walls in the entire building were uniformly produced using the tried-and-tested wall formwork, Mammut 350. The sharp finish produced the joint pattern that the architect desired. For the beams, the MevaFlex slab formwork system was used to produce the slab at a height of 28 metres.

b) New shuttering panels deliver excellent results

The flawless results required on the beams were achieved using new shuttering panels. 3S shuttering panels of the required size were prepared in order to create the desired pattern as if it had been produced by the imprints left by Mammut 350 panels. After the first use, the panels were turned over so that the clean, unused side could be employed for the next cycle. The results created an extremely regular design, not only does the pattern extend uniformly across the entire ceiling, but the openings for the lamps are also always in the middle of the shuttering panel imprint.

2. Superior quality finishes with alkus all-plastic facing

An architectural finish was required for all surfaces on this project. However, particularly high finish requirements applied in the meeting rooms, the shop, and the cafeteria. To fulfil these uniformly, MEVA organised its own training course on-site with regards to the preparation and maintenance of the alkus all-plastic facings used.

As the facing can be repaired using the same material, scratches and holes can be plugged flawlessly; at the same time, the facing retains its fundamental properties, preventing discolouration and enabling smooth, uniform surfaces to be achieved. The environmentally friendly all-plastic facing with its long service life is fitted as standard in MEVA’s formwork systems.

3. Extraordinary precision

For the 1-metre-thick outer walls, it was necessary to work meticulously, as the tolerance for misalignment of the formwork joints was only permitted to be 1 to 2 millimetres. That corresponds to about one quarter of the dimensional tolerance specified in the SIA standard 414/1, a typical industry standard. The reason for this is the natural stone façade that was precisely designed around the high window façades and columns. A greater deviation would have caused the concrete wall to protrude underneath the façade, but this was avoided.

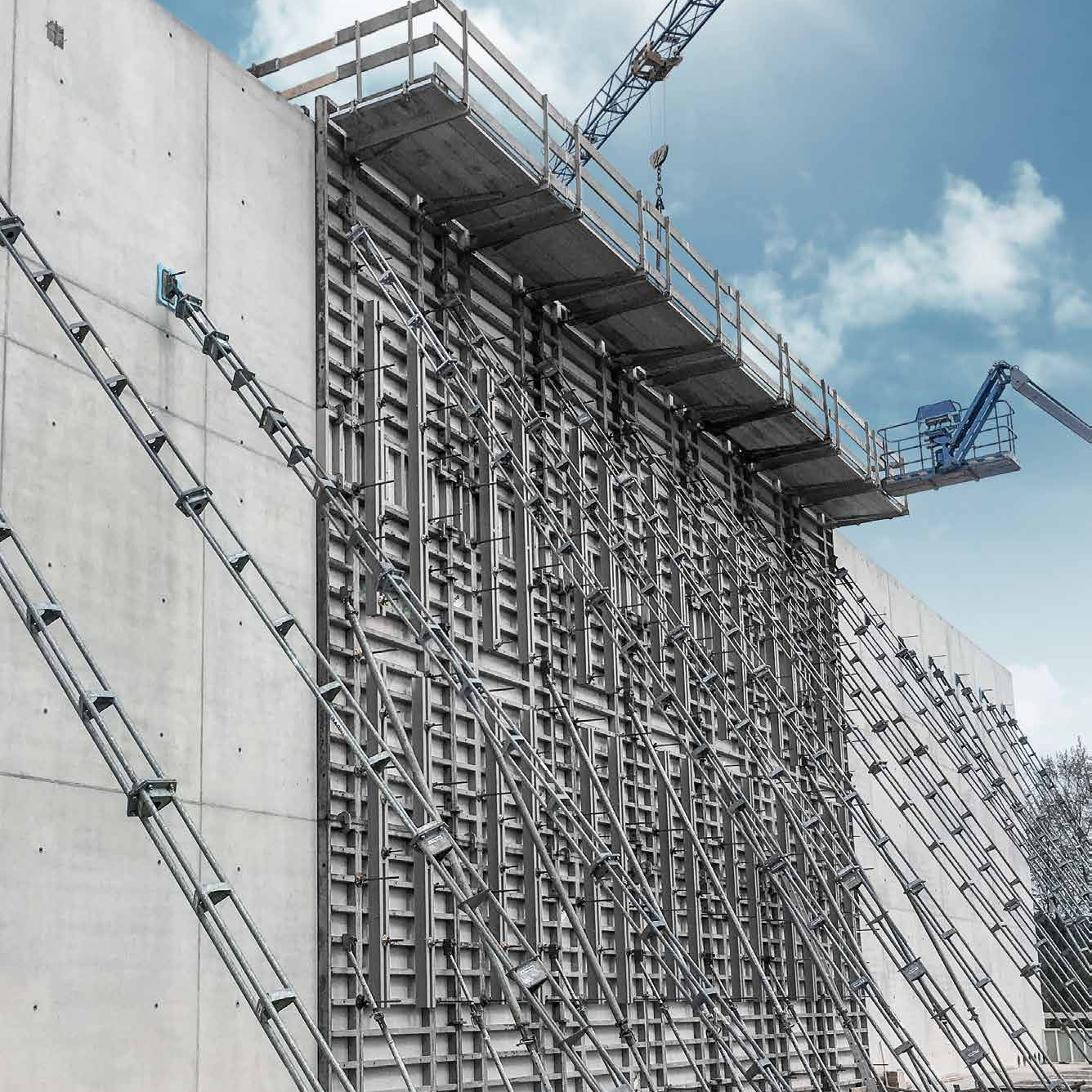

Using two Mammut 350 formwork sets, the 28-metre-high walls were formed in four 7-metre cycles. The KLK 230 climbing scaffold was used to erect and precisely align the formwork. Reinforced with Triplex heavy-duty props, the KLK 230 served as a scaffold for the alignment of the high formwork units.

4. Ease of use despite demanding requirements

a) High concrete pressure capacity makes work easier and faster

Due to the dimensional accuracy of the formwork and the high fresh-concrete pressure capacity of 100 kN/m², it was possible to pour concrete p to a height of 4 metres without taking the rate of placing into account. This was one less detail that the contractor had to worry about during construction, whilst still achieving the desired finish.

b) Adaptability aids efficiency

The Mammut 350 wall formwork proved to be an absolute all-rounder in the entire hall. The 3.5 metre by 2.5 metre panels were used horizontally in order to form the tall flights of stairs and also the 2.5-metre-thick concrete beams under the roof of the large hall. The KLK 230 climbing scaffold was mounted on the wall to enable alignment of the formwork, all whilst still achieving the uniform joint pattern.

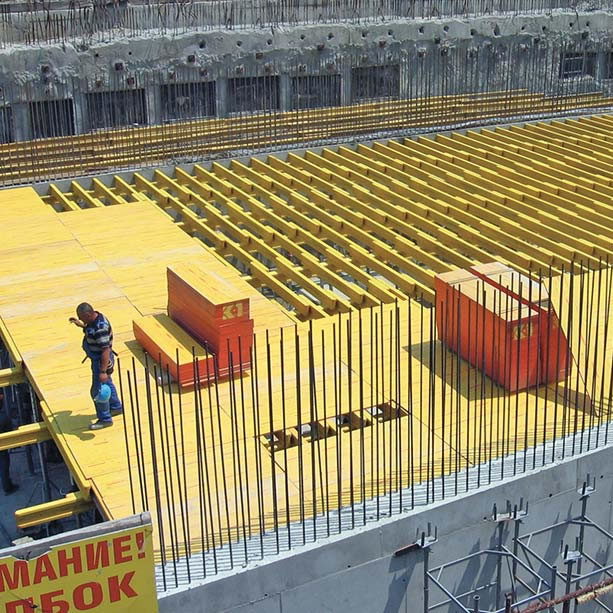

c) Flexible slab system saves time

The slabs of the exhibition rooms were implemented using the MevaDec standard slab formwork. Due to the system’s arbitrary grid pattern, it was possible to freely select the beam orientation, thus reducing the number of compensations and making the work easier and quicker. In more spacious rooms, the slabs were formed using the MevaFlex slab formwork supported by the flexible MEP shoring tower. Particular attention was also given to the atrium, which was constructed over five concreting cycles.

The Outcome

With the newly built extension, Zurich now has a new architectural eye-catcher and an outstanding port of call for art connoisseurs. Together, Marti AG and MEVA overcame the considerable challenges and created a structure that resembles a concrete sculpture.

"The art museum was a very interesting construction site. Thanks to reliable partners such as MEVA, we have done a really good job here." - Franz Bütler, Construction Manager at Marti AG

Featured Products

- Mammut 350 wall formwork

- MevaDec slab formwork

- MevaFlex slab formwork

- MEP shoring tower

- Triplex heavy duty props

- KLK climbing scaffold.

Details

Client: Marti AG Zurich

Project: Extension of Zürich Art Museum

Location: Zurich, Switzerland

Principal: Zürich, Amt für Hochbauten

Engineering & Support: MEVA Schalungs-Systeme AG, Seon.