Special MEVA design delivers solution to complex vertical louvre geometry

The three-kilometre extension currently under construction for the U6 line of Stuttgart's Stadtbahn light rail system will offer passengers a direct link from Gerlingen in the north-west of the city to the airport in the south. The route runs across the city and connects numerous districts. Once completed, the new extension will cut the journey time between Stuttgart city centre and the airport to only 30 minutes.

The extension project for the rail operator Stuttgarter Straßenbahnen AG (SSB) involves numerous construction companies. Of these, Züblin was awarded the biggest contract, which is for the ramp, tunnel and terminus structure at Stuttgart Airport. Faced with the task of building a highly complex vertical louvre wall, the contractor decided to call on MEVA's design expertise. The architecturally idiosyncratic wall structure is located at the Airport/Exhibition Centre terminus.

Premiere for wall concept

The process of designing and constructing the vertical louvre walls required a good deal of subtlety and ingenuity. "As this is the first time our company has built a wall of this kind, it was very difficult to predict the required effort," explains Züblin site manager Heiko Wagner. "But thanks to MEVA's support, it's been a very successful premiere." MEVA's engineers started by converting an undimensioned initial sketch from the tendering procedure into a detailed 3D model showing the exact angles, niches and spacings.

Project requirements

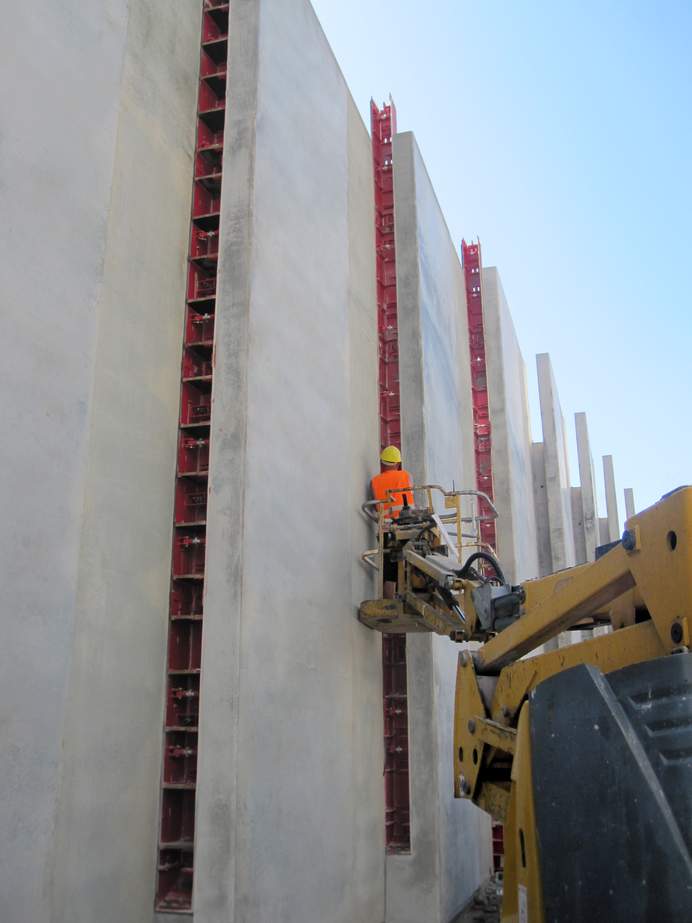

Rising to a height of up to 9.30 m, the vertical louvre walls are located at the upwardly open light rail terminus between the conference hotel to the north and airport to the south. The planned wall height varies in response to a nearby footpath and cycle track. The composition features an overlapping sequence of 4 m wide louvres. The walls project at the top and are tapered in thickness, a narrowing effect achieved by the rear face formwork. To speed up and streamline site operations, provision was also made for interlinking the special formwork panels.

Starting from the bottom

A total of 18 pour cycles are required to build the complex vertical louvre walls. The elaborate geometry was already reflected in the steelfixing operations, the shape of the louvre walls being traced out by the precise reinforcement layout at ground level. 15 cm high kickers were then cast to simplify subsequent assembly of the tall formwork units and support frames.

Three-part niche formwork

To achieve the required overlapping configuration with single-sided formwork, a special solution was needed to form the gaps between the individual louvres. This function was performed by a MEVA-designed niche formwork assembly that allowed efficient and straightforward creation of the required geometries. As the concept included the later illumination of the niches between the louvres, more than just a rectangular boxout was needed. A further recess had to be incorporated at the rear to accommodate the electrical fittings. A niche kicker was also required at ground level to take account of the varying angles formed with the joints between the precast-concrete track blocks. Then, as the largest of the three units, came the front niche formwork. Development of the ingenious technical solution called for a fair amount of creative engineering. Given the spatial constraints, the team opted for a steel assembly.

Detail solution

Several factors play a role in ensuring the reliable positioning of the niche formwork between the louvres. First, it is screwed through the frame to the front wall formwork. Tight-fitting timber board is then incorporated into the boxout to resist the fresh concrete pressure. A special L-shaped metal bracket is also fitted into the niche formwork, with the longer leg secured to the frame of the louvre formwork. In case of differences in pour height and fresh concrete pressures between two louvres, this provides horizontal stability by transferring the pressure to the frame. To facilitate removal of the niche formwork after casting, it is additionally fitted with hinged corners and designed with a trapezoidal shape with a narrower rear face. As a result, once the front part is free, the unit can be easily removed without friction. The hinged corners also allow the sides to be folded in, which further simplifies the stripping process.

North/south difference

Apart from delivering complex detail solutions, MEVA’s engineers had to devise smart concepts to meet challenges of a more general nature. The vertical louvre walls exhibit varying geometries on the northern and southern sides: the louvres are arranged in opposing directions and the rear-side taper also differs in response to the adjacent landscaping. While the 140 m long southern side is built with an inclined rear face, a channel is formed on the shorter, 93 m long northern side. The special shapes necessitated the use of custom-designed precision formwork that can be reused as the works progress. “Our procedures vary according to the area we’re working in,” explains site manager Heiko Wagner, referring to the additional complication of the north/south difference. “At the start, this required extreme concentration. But we got the hang of it after we’d done it two or three times. And you soon notice how MEVA’s designs are geared to on-site practice and making operations as easy as possible.”

When one becomes two

As the vertical louvre walls not only have different rear faces, but also project upwards beyond the excavation pit, the use of single-sided formwork is not possible over the full height. MEVA’s experts thus developed an intelligent solution to combine single- and double-sided operations. The STB 450 support frame and Mammut 350 heavy-duty formwork are used to cast the lower section against the pit wall. Here, the system’s ability to accommodate fresh concrete pressures of up to 100 kN/m² over the full surface is particularly beneficial as unlimited pour speeds are possible for heights of up to 4 m. Due to the different rear faces, the single-sided area has a wall thickness of approx. 1 m on the northern side and 1.3 m on the southern side. The single-sided area of the northern wall is also larger and is supported by three Triplex braces to resist the accordingly higher forces. The southern wall, on the other hand, only needs two of MEVA’s modular heavy-duty braces. In the upper part of the vertical louvre walls, single-sided is replaced by double-sided formwork. This approx. 2.5 m tall section is supported by a MEVA steel frame assembly. As the overall height of the vertical louvre walls is constant, the height difference between the single-sided sections on the northern and southern sides is offset by fitting a support plate to the steel frame assembly.

Bold approach to innovation

With the steel frame acting in a similar way to a dry tie, the formwork in the entire area of this frame requires no through ties. “Two-sided tying was originally planned,” points out Züblin project manager Christian Hoffmann. “To achieve a uniform appearance over all the concrete surfaces, this would have meant adding a regular pattern of blank cones to the single-sided area and involved an enormous effort.” MEVA’s proposal to work with a steel frame paved the way for a formwork assembly that essentially amounts to two single-sided arrangements. The absence of tie holes with this solution automatically eliminates the need for blank cones, thereby vastly simplifying and speeding up operations. It also allows the achievement of a more even and uniform surface finish. The idea won over Züblin’s experts and also appealed to the principal Stuttgarter Straßenbahnen AG. A delighted Christian Hoffmann was quick to praise the creative formwork designers at partner MEVA: “Their proposals added real value to our project.”

Smooth and textured architectural concrete

Eliminating the need for blank cones was also useful in meeting the stringent architectural concrete requirements placed on the project. To achieve extra-smooth and uniform concrete surfaces, the special formwork was fitted with alkus all-plastic facings at the MEVA plant. The facings were screwed down from behind to avoid screw marks on the surface. Joints and angles were welded with the same synthetic material used for the facings. This prevents the escape of cement paste and thus delivers very high-quality results. The smooth surfaces formed by the alkus all-plastic facing are bounded by a soft wood-grain finish at the louvre edges, achieved through the incorporation of textured formliners. Inch-perfect flush-fitting of the facings in the special formwork helped to enhance the harmonious appearance of the wall composition.

“Thanks to MEVA’s special design expertise, we now have a formwork solution tailored to our requirements,” says site manager Wagner. “Which is a real blessing on such a complex project.” Project manager Hoffmann adds: “For us, the convincing solutions to a whole string of design challenges will be a massive help in delivering the project successfully.”